What exactly is a "jumping stopper," and why is it an essential element in various industries and applications? Understanding the concept of a jumping stopper might initially seem perplexing, but its significance cannot be underestimated. Whether used in mechanical engineering, safety applications, or other technical fields, jumping stoppers play a crucial role in maintaining efficiency and safety. This article will delve deep into the multifaceted nature of jumping stoppers, exploring their importance, applications, and the technical know-how required for their optimal usage.

Jumping stoppers are an integral component in many systems designed to prevent sudden or unintended movements. These devices are incredibly versatile, finding applications across a wide range of industries, from automotive to aerospace, and even in household appliances. The primary purpose of a jumping stopper is to ensure stability and control, acting as a fail-safe mechanism that prevents potential accidents or malfunctions. By examining the various types and functions of jumping stoppers, we can appreciate their critical role in modern technology.

In this comprehensive guide, we will explore the historical development of jumping stoppers, their mechanical and scientific principles, and the industries that rely on them. Our journey will include insights into the materials used, the design innovations, and the future trends shaping the evolution of jumping stoppers. We will also address common questions and concerns, providing a holistic understanding that underscores the importance of these seemingly simple yet vital components.

Table of Contents

- Biography and Overview

- Understanding the Role of Jumping Stoppers

- Historical Development of Jumping Stoppers

- Types and Applications of Jumping Stoppers

- Mechanical Principles of Jumping Stoppers

- Material Selection for Jumping Stoppers

- Design and Innovation in Jumping Stoppers

- Industry Reliance on Jumping Stoppers

- Safety and Regulations Concerning Jumping Stoppers

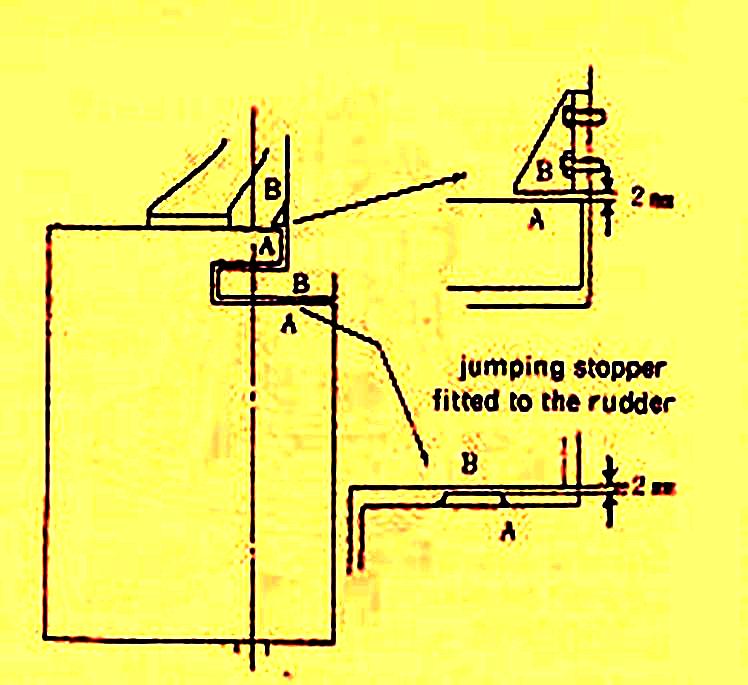

- Installation and Maintenance of Jumping Stoppers

- Future Trends and Developments

- Economic Impact of Jumping Stoppers

- Environmental Considerations

- Common Issues and Troubleshooting

- Frequently Asked Questions

- Conclusion

Biography and Overview

While jumping stoppers may not be associated with a specific person or celebrity, their development and implementation have a rich history worth exploring. These devices emerged from the need to control and stabilize mechanical systems, evolving alongside technological advancements in various industries. The concept of a jumping stopper is rooted in basic mechanical principles, yet its design and utility have become increasingly sophisticated over time.

The following table provides an overview of the typical specifications and characteristics of jumping stoppers:

| Feature | Description |

|---|---|

| Function | Prevents unintended movement or vibration in mechanical systems |

| Applications | Automotive, aerospace, manufacturing, household appliances |

| Materials | Metal alloys, polymers, composites |

| Design Variations | Spring-loaded, hydraulic, pneumatic |

| Safety Standards | Compliance with industry-specific regulations |

| Maintenance | Regular inspection and replacement |

Understanding the Role of Jumping Stoppers

Jumping stoppers serve a critical function in mechanical systems, acting as a safeguard against unexpected or dangerous movements. They are engineered to absorb energy, dampen vibrations, and provide stability, ensuring the smooth operation of machinery and equipment. This section will explore the physics behind their functionality, illustrating how jumping stoppers contribute to the efficiency and safety of complex systems.

At their core, jumping stoppers are designed to counteract forces that could lead to instability or damage. These forces might include vibrations from external sources, internal mechanical interactions, or even environmental factors like temperature fluctuations. By mitigating these forces, jumping stoppers help maintain the integrity of the system they are part of, reducing the risk of failures or accidents.

Consider a simple example of a jumping stopper used in an automotive application. In this context, a jumping stopper might be employed to stabilize the suspension system, absorbing shocks and reducing the impact of road irregularities. This ensures a smoother ride for passengers and helps protect the vehicle's components from wear and tear. The same principles apply across different industries, where jumping stoppers are customized to meet specific requirements and challenges.

Historical Development of Jumping Stoppers

The history of jumping stoppers is intertwined with the broader evolution of mechanical engineering and industrial design. Early iterations of these devices were rudimentary, often relying on basic materials and simple mechanisms to achieve their purpose. However, as technology advanced, so too did the sophistication of jumping stoppers, incorporating new materials, designs, and functionalities.

Initially, jumping stoppers were used primarily in large industrial applications, where the need for stability and control was paramount. Over time, their use expanded to include smaller, more consumer-oriented products, such as household appliances and personal vehicles. This shift was driven by the growing demand for reliability and safety in everyday items, as well as the increasing complexity of modern machinery.

The development of jumping stoppers has been marked by several key milestones, including the introduction of new materials like polymers and composites, which offer improved durability and performance. Additionally, advances in computer-aided design (CAD) and manufacturing techniques have enabled the creation of more precise and efficient jumping stoppers, tailored to specific applications and requirements.

Types and Applications of Jumping Stoppers

Jumping stoppers come in a variety of forms, each designed to address specific challenges and applications. Understanding the different types of jumping stoppers and their respective uses is essential for selecting the right solution for a given situation. This section will explore the most common types of jumping stoppers and their applications across various industries.

Spring-Loaded Jumping Stoppers

Spring-loaded jumping stoppers are among the most common types, utilizing the force of a spring to absorb energy and dampen vibrations. These stoppers are often adjustable, allowing for customization based on the specific needs of the application. They are widely used in automotive suspensions, machinery mounts, and other dynamic systems where flexibility and adaptability are required.

Hydraulic Jumping Stoppers

Hydraulic jumping stoppers use fluid pressure to counteract forces and provide stability. These devices are particularly effective in applications where precise control over movement is essential, such as heavy machinery, aircraft landing gear, and industrial equipment. The ability to fine-tune the hydraulic pressure allows for a high degree of customization and efficiency.

Pneumatic Jumping Stoppers

Pneumatic jumping stoppers operate on similar principles to hydraulic stoppers, but use compressed air instead of fluid. This makes them ideal for applications where weight and space are considerations, such as in portable equipment and lightweight machinery. Pneumatic stoppers offer rapid response times and can be easily integrated into existing systems.

Composite and Advanced Material Jumping Stoppers

With the advent of new materials and technologies, jumping stoppers made from composites and advanced materials have become increasingly popular. These stoppers offer superior performance, durability, and resistance to environmental factors, making them suitable for challenging applications in aerospace, marine, and other high-performance industries.

Mechanical Principles of Jumping Stoppers

The effectiveness of jumping stoppers is rooted in fundamental mechanical principles, such as energy absorption, damping, and force distribution. Understanding these principles is vital for designing and implementing jumping stoppers that meet the specific needs of an application.

Energy absorption is a key function of jumping stoppers, allowing them to reduce the impact of sudden movements or vibrations. This is achieved through the conversion of kinetic energy into other forms, such as heat, which is then dissipated safely. The materials and design of the stopper play a crucial role in determining its energy absorption capacity.

Damping is another critical function, referring to the reduction of oscillations or vibrations within a system. Jumping stoppers achieve this by providing resistance to motion, slowing down the rate of movement and preventing excessive oscillations. This helps maintain stability and control, ensuring the smooth operation of machinery and equipment.

Force distribution is the final principle that underpins the functionality of jumping stoppers. By evenly distributing forces across a system, these devices help prevent localized stress and potential damage. This is particularly important in applications where uneven forces could lead to mechanical failure or reduced performance.

Material Selection for Jumping Stoppers

The choice of materials is a critical factor in the design and performance of jumping stoppers. Different materials offer varying levels of strength, durability, and resistance to environmental factors, making it essential to select the right material for a given application. This section will explore some of the most common materials used in jumping stoppers and their respective advantages.

Metal Alloys

Metal alloys, such as steel and aluminum, are commonly used in jumping stoppers due to their strength and durability. These materials are ideal for heavy-duty applications, where the stopper must withstand significant forces and wear over time. Additionally, metal alloys offer good resistance to temperature fluctuations and corrosion, further enhancing their suitability for demanding environments.

Polymers

Polymers, such as rubber and plastic, are often used in jumping stoppers for applications requiring flexibility and lightweight characteristics. These materials are particularly effective in damping vibrations and absorbing energy, making them suitable for use in automotive suspensions and other dynamic systems. Polymers are also resistant to many environmental factors, including moisture and chemicals, which can extend the lifespan of the stopper.

Composites

Composites are increasingly being used in jumping stoppers due to their superior performance and versatility. These materials combine the benefits of multiple components, such as the strength of metal alloys and the flexibility of polymers, to create a high-performance solution. Composites are particularly well-suited for applications in aerospace, marine, and other industries where weight and performance are critical considerations.

Design and Innovation in Jumping Stoppers

As technology continues to advance, so too do the design and capabilities of jumping stoppers. Innovations in materials, manufacturing techniques, and design processes have led to the development of more efficient and effective jumping stoppers, tailored to meet the specific needs of modern applications.

One of the most significant innovations in jumping stopper design is the use of computer-aided design (CAD) software. This technology enables engineers to create precise and complex designs that can be easily tested and refined, ensuring optimal performance and reliability. Additionally, CAD software allows for the rapid prototyping of new designs, speeding up the development process and reducing costs.

Another important area of innovation is the integration of smart technologies into jumping stoppers. These devices can be equipped with sensors and monitoring systems that provide real-time feedback on their performance, allowing for more accurate control and maintenance. Smart jumping stoppers can also be integrated into larger systems, such as the Internet of Things (IoT), enabling remote monitoring and control.

Industry Reliance on Jumping Stoppers

Jumping stoppers are used across a wide range of industries, each with its unique requirements and challenges. Understanding the specific needs of different industries is essential for designing and implementing jumping stoppers that meet their demands.

Automotive Industry

In the automotive industry, jumping stoppers are used to improve the performance and safety of vehicles. They are often employed in suspension systems, where they help absorb shocks and vibrations, ensuring a smoother ride for passengers. Jumping stoppers are also used in engine mounts and other components, where they help reduce noise and wear.

Aerospace Industry

The aerospace industry relies on jumping stoppers to ensure the safety and reliability of aircraft. These devices are used in landing gear, control surfaces, and other critical components, where they help absorb shocks and vibrations, reducing the risk of failure. Jumping stoppers are also used in spacecraft, where they help protect sensitive equipment from the harsh conditions of space.

Manufacturing Industry

In the manufacturing industry, jumping stoppers are used to improve the efficiency and safety of machinery and equipment. They are often employed in conveyor systems, where they help absorb shocks and vibrations, ensuring smooth and reliable operation. Jumping stoppers are also used in robotic systems, where they help reduce wear and improve precision.

Consumer Products

Jumping stoppers are also used in a wide range of consumer products, such as household appliances and electronics. These devices help improve the performance and durability of products, ensuring they operate smoothly and reliably. Jumping stoppers are often used in washing machines, refrigerators, and other appliances, where they help reduce noise and vibrations.

Safety and Regulations Concerning Jumping Stoppers

Safety is a critical consideration in the design and use of jumping stoppers. These devices must comply with industry-specific regulations and standards to ensure they operate safely and effectively. Understanding these regulations is essential for selecting and implementing jumping stoppers that meet the necessary safety requirements.

One of the most important safety standards for jumping stoppers is the International Organization for Standardization (ISO) standards. These standards provide guidelines for the design, testing, and use of jumping stoppers, ensuring they meet the necessary safety and performance requirements. Compliance with ISO standards is often a requirement for the use of jumping stoppers in many industries.

In addition to ISO standards, jumping stoppers must also comply with industry-specific regulations, such as those set by the American Society of Mechanical Engineers (ASME) and the Society of Automotive Engineers (SAE). These organizations provide guidelines for the design and use of jumping stoppers in specific applications, ensuring they operate safely and effectively.

Installation and Maintenance of Jumping Stoppers

Proper installation and maintenance are essential for ensuring the performance and longevity of jumping stoppers. This section will provide guidelines for the installation and maintenance of jumping stoppers, helping to ensure they operate safely and effectively.

The first step in installing a jumping stopper is to select the right device for the application. This involves considering the specific needs and requirements of the system, such as the forces and vibrations it will encounter. Once the appropriate jumping stopper has been selected, it must be installed according to the manufacturer's guidelines, ensuring it is securely attached and properly aligned.

Regular maintenance is also important for ensuring the performance and longevity of jumping stoppers. This involves inspecting the stopper for signs of wear or damage, and replacing it as necessary. Additionally, jumping stoppers should be cleaned and lubricated regularly to ensure they operate smoothly and efficiently.

Future Trends and Developments

The future of jumping stoppers is shaped by ongoing technological advancements and changing industry needs. This section will explore some of the key trends and developments that are expected to influence the design and use of jumping stoppers in the coming years.

One of the most significant trends is the increasing use of smart technologies in jumping stoppers. These devices can be equipped with sensors and monitoring systems that provide real-time feedback on their performance, allowing for more accurate control and maintenance. Smart jumping stoppers can also be integrated into larger systems, such as the Internet of Things (IoT), enabling remote monitoring and control.

Another important trend is the growing demand for environmentally friendly jumping stoppers. This is driven by increasing awareness of environmental issues and the need for sustainable solutions. As a result, there is a growing focus on developing jumping stoppers that are made from recyclable materials and have a minimal environmental impact.

Economic Impact of Jumping Stoppers

Jumping stoppers play a crucial role in many industries, contributing to their efficiency and safety. This section will explore the economic impact of jumping stoppers, highlighting their importance in modern technology and industry.

Jumping stoppers help improve the performance and reliability of machinery and equipment, reducing the risk of failures and accidents. This leads to cost savings for businesses, as they can operate more efficiently and avoid costly repairs and downtime. Additionally, jumping stoppers contribute to the longevity of products, reducing the need for replacements and further cost savings.

The economic impact of jumping stoppers is also evident in their role in supporting innovation and technological advancements. These devices enable the development of more advanced and efficient systems, driving progress and growth in various industries.

Environmental Considerations

Environmental considerations are becoming increasingly important in the design and use of jumping stoppers. This section will explore the environmental impact of jumping stoppers and the steps being taken to reduce their impact.

One of the main environmental concerns associated with jumping stoppers is the use of non-recyclable materials. Many traditional jumping stoppers are made from metal alloys and polymers that are not easily recyclable, leading to waste and environmental impact. However, there is a growing focus on developing jumping stoppers that are made from recyclable materials, reducing their environmental impact.

Another important consideration is the energy consumption associated with the production and use of jumping stoppers. Efforts are being made to develop more energy-efficient manufacturing processes and designs, reducing the overall energy consumption and environmental impact of jumping stoppers.

Common Issues and Troubleshooting

Despite their importance and reliability, jumping stoppers can sometimes encounter issues that affect their performance. This section will explore some of the most common issues associated with jumping stoppers and provide troubleshooting tips for addressing them.

Wear and Tear

One of the most common issues with jumping stoppers is wear and tear, which can lead to reduced performance and reliability. This can be addressed by regularly inspecting the stopper for signs of wear or damage and replacing it as necessary. Additionally, regular cleaning and lubrication can help reduce wear and prolong the lifespan of the stopper.

Improper Installation

Another common issue is improper installation, which can lead to misalignment or other issues that affect performance. This can be addressed by ensuring the stopper is installed according to the manufacturer's guidelines, and by regularly checking its alignment and attachment.

Material Degradation

Jumping stoppers can also experience material degradation over time, particularly if they are exposed to harsh environmental conditions. This can be addressed by selecting materials that are resistant to environmental factors and by regularly inspecting the stopper for signs of degradation.

Frequently Asked Questions

1. What is a jumping stopper used for?

Jumping stoppers are used to prevent unintended movement or vibration in mechanical systems, ensuring stability and control. They are used across a wide range of industries, including automotive, aerospace, manufacturing, and consumer products.

2. What are the different types of jumping stoppers?

The most common types of jumping stoppers are spring-loaded, hydraulic, pneumatic, and composite. Each type has its unique advantages and applications, depending on the specific needs of the system.

3. How are jumping stoppers installed?

Jumping stoppers are installed according to the manufacturer's guidelines, ensuring they are securely attached and properly aligned. Proper installation is essential for ensuring the performance and reliability of the stopper.

4. How are jumping stoppers maintained?

Regular maintenance is important for ensuring the performance and longevity of jumping stoppers. This involves inspecting the stopper for signs of wear or damage, cleaning and lubricating it regularly, and replacing it as necessary.

5. What are the environmental considerations associated with jumping stoppers?

Environmental considerations include the use of non-recyclable materials and energy consumption associated with production and use. Efforts are being made to develop jumping stoppers made from recyclable materials and with more energy-efficient designs.

6. What are the future trends in jumping stoppers?

Future trends include the increasing use of smart technologies, the growing demand for environmentally friendly solutions, and the development of more advanced and efficient systems.

Conclusion

Jumping stoppers are a vital component in many mechanical systems, providing stability and control to ensure the safe and efficient operation of machinery and equipment. Their versatility and adaptability make them essential across a wide range of industries, from automotive to aerospace and beyond. By understanding the principles, applications, and future trends of jumping stoppers, we can appreciate their importance and continue to innovate and improve these critical devices.

As technology continues to advance, jumping stoppers will play an increasingly important role in supporting innovation, efficiency, and sustainability. By selecting the right materials, designs, and technologies, we can develop jumping stoppers that meet the evolving needs of modern industry and contribute to a safer, more efficient world.